Three Tips for Better Millwork

10 09 2014

In the last blog post I discussed how better saw set ups can minimize sanding and make better joinery. This time around, lets look at three ways you can achieve much better (read smoother) cuts when cutting millwork on the router table. The three methods share a common thread, that of eliminating vibration. Vibration is he enemy of smooth cuts. Vibration shows up as scallops in your cut profile, and especially when making moldings, sanding these out can be a lot of work.

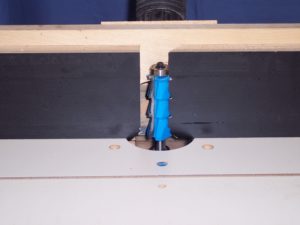

The first tip is to create a "Zero Clearance" opening in the fence, essentially burying the cutter in a sacrificial face on the fence. This supports the stock being cut right at the point where the bit exits the wood so tear out is pretty well eliminated. The extended face also supports the stock right up to the bit so vibration is reduced as well.

The second technique is pretty simple too. You want to insure proper dust collection, especially at the fence. chips not being effectively removed from the cutting area create two problems: First, chips can get caught between the carbide edge and the stock so that they get 'slammed' into the stock creating vibration and leaving tiny dents that need to be sanded out later. Second, the excess chips can get caught between the stock and the fence which keep the part slightly away from the fence which also increases vibration by removing support. Having adequate airflow through the fence removes the chips and the problems they can cause.

Lastly, runout will cause vibration and lead to more sanding. Runout is the small side to side movement allowed by the bearings in a shaft. EVERY rotating tool has some, but worn bearings or a bent shaft increases runout to unacceptable proportions. Insuring that your router is in good repair is important to getting the best cut. Checking your collet for dirt and grime helps too. excess dirt in the collet cause the bit to not seat properly increasing runout as well. Finally, there are times when you will need to use an extension. Just remember that every part added to the tool shaft has it's own runout, and these tiny measurements add up. Careful set up can help minimize the results.

I say it with each blog post, but we are always eager to hear from all of you as well, so feel free to comment here on the blog, on our Facebook page, or via Twitter. -2Sand.com