Slurry Sanding

09 27 2013

The open pores of woods like walnut or oak must be filled before a truly fine finish can be acheived. Even with extensive sanding and several coats of finish, the open pores will be felt through the topcoat. Slurry sanding is an old technique that can provide great results with modern supplies.

Several products are available to fill pores prior to finishing, but are sometimes difficult to use, may change the appearance of woods chosen for their specific color, or interfere with the finishing program to be applied. So I like to reproduce an old technique that has worked for centuries: slurry sanding, also known as flowed finish or by other terms. Traditionally, a wet finsish is applied, then rubbed out with pumice stone, and allowed to dry. Shellac is highly recommended for this process since it dried quickly and works well with most finishes.

Before quality sandpaper was commercially available, pumice stone was used as we would a fine grit sandpaper. Sanding like this with the surface wetted keeps the sanding dust in the wet finish, creating a fine slurry that is forced into the pores of the wood, creating a very smooth surface but does not alter the look of the wood. Because the slurry is made up of the wood being filled, there is no issue with color matching. If the wood is to be stained, it is stained first, so again the match will be perfect. No filler will take stain or finish as exactly as the wood itself, so this method keeps the wood color true.

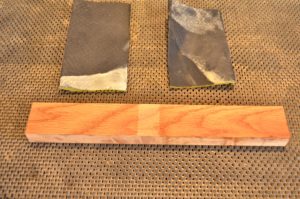

For oil finishes, I use the oil itself, wetting the wood, then HAND sanding it out with a fine grade of wet/dry sandpaper. You must use a quality paper made to be used wet or you risk having the grit fall off the paper into your finish. Here I have a sample part of red oak. One side is sanded dry in the same order and grit as the other which is sanded wet for the last two grits. The slurry side is then carefully wiped clean and both sides oiled a final time. In the low angle light, you can clearly see the difference.

If you plan to use a top coat, then shellac is best to keep the part wet as the last two sanding steps are carried out. A lighter weight of shellac is used to keep it wet a bit longer than normal. If you do not mix your own shellac, then cut the pre-mixed with a bit of alcohol to thin it out. Shellac won't interfere with most finishes once it is dry.

We hope that you find this information useful, and we would love to share your tips and tricks with our readers as well! You can share them by commenting here on this blog, on our Facebook page, or via Twitter. -2Sand.com

Search the blog