True Grits

08 31 2012

To be honest, writing this blog every few weeks is a bit of a challenge. After all, we are a sanding supplies company. We want our company blog to be relevant to our customers, but frankly finding new sanding topics is tough! Fortunately, I have you folks to fall back on. We get many inquiries through our website, Facebook and Twitter accounts where people can ask questions and discuss their concerns. For example, Troy Donson wanted to know what the different abrasive materials are good for. Why, for example, you might want to use Silicon Carbide as opposed to Garnet. So I spent some time with RJ, and here is his take on the subject:

Garnet is a natural abrasive material. It was originally a substitute for the actual glass that was used in early comercial papers. It was easier to work with and created more consistent particles than glass. It is relatively soft when measured against modern abrasives so it does not hold up as well to hard use, but that makes it desireable to some. Many purists still prefer it for hand sanding since they fell that it wears smooth in use, effectively raising the grit as it gets used. A fresh sheet might start removing material like 120 but by the time the sanding is done, the scratches left behind are more like 150 or even 200 without having switched papers!

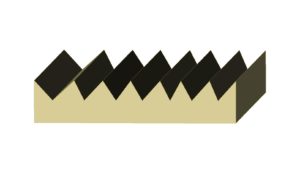

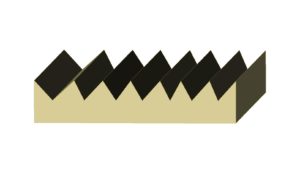

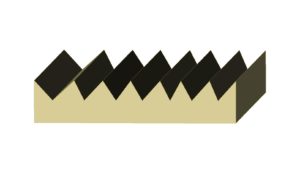

Aluminum Oxide is much harder and more aggressive. Since it is a man-made material, the particles can be very precisely controlled. A single oversized grain on a disk can leave very noticable swirl marks. Aluminum Oxide tends to leave very sharp points in both the peaks and valleys or the material surface when looked at under a microscope. This creates highly reflective surfaces that light reacts with in predictable ways.

Silicon Carbide is another man-made material. It too is very hard and can be sorted into very precise grit sizes. It tends to be less angular than Aluminum Oxide, so while it still leaves sharp peaks, the valley bottoms are more rounded. These round bottoms disperse light differently leaving a very different "sheen" than Aluminum Oxide of the same grit.

Silicon Carbide is another man-made material. It too is very hard and can be sorted into very precise grit sizes. It tends to be less angular than Aluminum Oxide, so while it still leaves sharp peaks, the valley bottoms are more rounded. These round bottoms disperse light differently leaving a very different "sheen" than Aluminum Oxide of the same grit.

Steel Wool or Abralon disks tend to leave rounded points on both peaks and valleys, adding a thrid level of light refraction or sheen. But, of course, these products are typically used not on base surfaces, but on finished surfaces, so removing peaks and filling valleys is what we want from them.

Steel Wool or Abralon disks tend to leave rounded points on both peaks and valleys, adding a thrid level of light refraction or sheen. But, of course, these products are typically used not on base surfaces, but on finished surfaces, so removing peaks and filling valleys is what we want from them.

A typical industrial strategy may be to start with Aluminum Oxide (for aggressive removal), switch to Silicon Carbide as higher grit numbers are reached (to still remove material but without the sharp bottomed valleys), and finish off with Abralon or the old fashioned Steel Wool to take down the final sharp peaks.

RJ had a lot to say about how to select the right grit to start with as well as how far to skip down between grits as you sand. We will talk about that in the next blog. Meanwhile, please feel free to add your comments here on the blog, on our Facebook page, or via Twitter. Let us know what you think! -2Sand.com