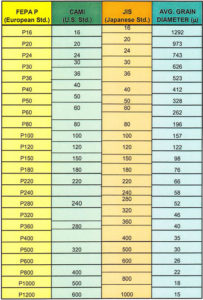

Sandpaper Grit Chart

02 24 2015

No matter what sort of sanding supplies you are reaching for, the first decision you need to make is what sandpaper grit to start with. But the sizing on sandpaper grit numbers seem to be backwards. Like wire sizes, smaller numbers actually mean larger. In the case of sandpaper, this means bigger particles and more aggressive stock removal. And then, to add to the confusion, a while back manufacturers changed the numbering standards almost without bothering to mention it, or why! We are here to help sort it out for you.

First, you need to understand that there are different agencies that decide what grits are what numbers! There is the Coated Abrasives Manufacturer's Institute (CAMI) in the US and the Federation of European Producers of Abrasives (FEPA) in Europe. For a long time, sanding supplies here in the US were labeled with the CAMI system which just used numbers. More recently, most manufacturers have switched to the FEPA system with a "P" preceding the number. But the two systems are NOT exactly the same, so an 80 grit sanding disk is NOT exactly the same as one labeled "P80". 80 grit abrasive particles average 201 microns while P80 averages 192. So P80 sandpaper is slightly more aggressive than 80 grit. Add to this that the Japanese abrasives scale is different than the other two, and the plot thickens!

And while the rougher abrasives are pretty close if not exactly the same, at higher numbers, the differences become greater so a 400 grit CAMI falls between FEPA's P600 and P800!

Now in truth, for most of us the difference between the CAMI and FEPA scales makes little enough difference on a day to day basis, but it is important to know about since there are times when the grit choice is important. I know that at times I have rubbed a new sheet of sandpaper on a cement floor to "break down" the grit a little bit because it was just a little too aggressive for the task at hand. So next time you are wondering if the 120 grit sanding disk in your hand actually is cutting faster than you thought it would, be sure to check the actual label or talk to your supplier,and see which standard was used for grading!

As ever, we invite you to share your thoughts and knowledge with us by commenting here on the blog, on our Facebook page, or via Twitter. -2Sand.com

And if you like these blogs, be sure to share them with friends and co-workers!