Sanding Equipment Maintenance

Posted by The Team at 2Sand on 02 22 2023

Everyone has heard, “If it can go wrong, it will”. And this maxim seems particularly true of machines and mechanical devices. But smart businesses and crafts people know that while failure and breakdowns cannot be eliminated, the interruptions they cause can be minimized with a bit of planning and routine maintenance.

It is all too easy to delay or even skip maintenance tasks since they take time that is not only not billable but is also an expense. But when machines break down, it will not be at a convenient time in between jobs. The best defense against this is regular, scheduled maintenance. The plan should be to schedule when machines and tools are pulled offline to inspect, clean, and service them as recommended. It will take time from production, but not nearly as much as a breakdown will. And by planning downtime you control when the interruption happens.

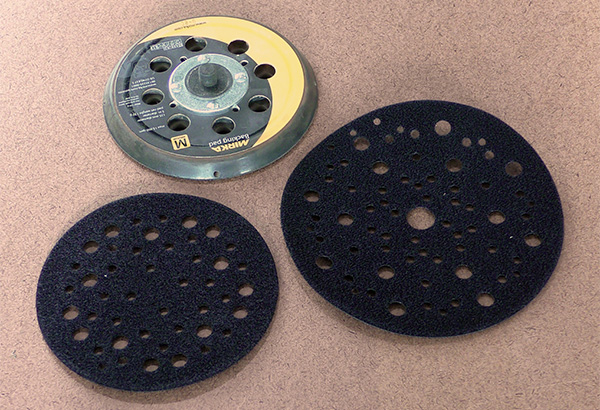

We usually think about service schedules for big machines like widebelt sanders, but your smaller tools are just as important to keep work flowing. And it often pays to have commonly used repair parts in house. Having the right Backup Pads for your random orbit sander on hand means they can be changed in a few minutes, so the interruption is almost unnoticed. Same holds true for tracking sensors in your widebelt sander. They go bad fairly regularly, but are cheap enough to keep one on hand. Pad Protectors are very cost effective to have around to keep discs on the sander as well as protect the more expensive Backup Pads.

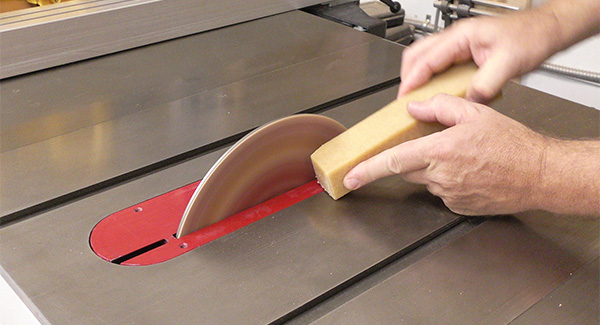

Do not forget the other parts that support your equipment. Inspecting things like cords and dust collection hoses will allow you to order replacements before they fail, keeping your team hard at work. Remember also that some items have a shelf life. For example, Sanding Belts are subject to breaking at the joint after a year, so be sure to rotate your stock by date and save some money by ordering only what you need for the next few months. Belt Cleaning Sticks are also a service item that will extend the life of your sanding supplies and reduce overheating in tools and machines.

Large or small, keeping your tools and equipment maintained and properly serviced will minimize breakdowns and the interruptions they can cause to your schedule. You should really schedule maintenance and hold to the schedule as if it were a paying job, because it really is