How to Wet Sand - A Guide to Wet Sanding All Surfaces

Posted by Rebecca Henderson on 01 24 2023

Sanding can improve the overall finish of objects made from several materials. However, choosing between dry and wet sanding processes can be tricky, especially if you’re not familiar with what’s involved. While the idea of sanding is fairly straightforward, it pays to know what you’re doing before you take sanding just a little too far. It’s much easier to reduce the material in front of you than it is to add some back on.

To help you understand wet sanding, we’ve put together a short guide on the process. We’ll compare wet and dry sanding to give you an idea of what each approach offers, as well as what techniques to use when wet sanding various materials. We certainly could dedicate an entire post to wet sanding each type of material, but this guide will give you a broad overview to work from. Like with any other finishing process, there’s no better teacher than trial and error.

If you want to learn how to wet sand, you’ve come to the right place. Let’s dive in with a look at the main differences between dry sanding and wet sanding.

Key Takeaways:

- Wet sanding requires specific waterproof sandpaper and is almost always done by hand.

- Because wet sanding is a finishing process, you’ll likely use high-grit sandpaper, from 1000 grit to 3000 grit and above. Compare this to dry sanding, which typically begins with 600- or 800-grit sandpaper.

- It’s best to use a backing pad when wet sanding to achieve a uniform finish.

- Instead of using small circles as you would with dry sanding, wet sand in a straight line, first horizontally and then vertically.

Wet Sanding vs. Dry Sanding

As the names might suggest, wet and dry sanding describe two very different processes. To break down the differences between these two processes, let’s take a closer look at each. Wet sanding, in comparison to dry sanding, just adds another element to the mix to achieve that smooth, lasting finish.

Dry Sanding

If you’re looking for a more aggressive approach, dry sanding allows you to take off more material in a quick fashion. It’s a great way to rough in the shape of your project with low-grit sandpaper. You can dry sand by hand or with power tools, but most often you’ll use small circles to remove material and minimize deep scratches.

Dry sanding can create a huge mess with all the dust and debris flying off the surface. There’s no lubricant required besides elbow grease. However, it’s often necessary to begin with lower grits of sandpaper when dry sanding and then pick up where you left off with wet sanding to finish.

Wet Sanding

The process of wet sanding is most often used to finish a project. You’ll use a light touch to refine the surface, which can take time. Wet sanding often takes advantage of higher-grit sandpaper to smooth out details and achieve a more desirable finish.

Wet sanding doesn’t just use water to lubricate the wet sanding-specific sandpaper. You can also use WD-40 if you’re sanding bare metal. In some cases, you may even want to add a bit of detergent to help reduce water tension on your sanding surface. This can prevent the sandpaper from catching and causing deep scratches.

Most sandpaper used for wet sanding requires a backing pad. As the water soaks into the pores of the sandpaper, it becomes flimsy and can easily fold back on itself. The backing pad not only prevents this from happening but can also help create a smoother finish than using your hands alone. The ridges and valleys of your fingers can easily translate to a surface when wet sanding, but not when using a sanding block.

You can also purchase sanding blocks to use when wet sanding. This is most commonly done in sanding drywall. As you wet sand, you’ll want to use linear movements for a uniform finish. With each pass, you’ll alternate directions in a perpendicular motion, going horizontal and then vertical or vice versa.

Benefits of Wet Sanding

One of the biggest differences between wet and dry sanding can be found in how much dust you produce during each process. With wet sanding, all those dust particles build up on the sandpaper instead, but they’re carried away by the water/liquid you use to wet the sandpaper. This helps not only to cut down on mess but efficiently remove material from the surface to prevent further scratches.

In addition, wet sanding is most often used as a finishing process. Any large scratches left by the dry sandpaper practically vanish with wet sanding. You can use this process to smooth out the pores of the wood and remove fine dust trapped within it. When wet with oil, this type of sandpaper can also achieve a satin finish when used on wood. In automotive paint correction, wet sanding is one of the first steps in preparing the paint for buffing and polishing.

You can also use wet sanding techniques on other types of finishes, many of which we’ll discuss below. These include sealant, varnish, polyurethane, metal, plastic, marine vessels, and more. Wet sanding mirrors dry sanding in versatility, but it can provide a finishing touch unmatched by most power tools.

How to Wet Sand

There are many surfaces you can wet sand, but each requires a bit of a unique approach. Depending on which type of material you’re working with and your time constraints, you’ll want to soak your sandpaper for anywhere from 15 minutes to overnight. The important thing to remember is that the sandpaper will work best as long as the paper itself is saturated.

Plastic Wet Sanding

Wet sanding plastic, in contrast to other wet sanding processes, does require lower grit sandpaper. You’ll want to use 180-grit sandpaper for the most aggressive approach. Use 600-grit sandpaper to finish any details. You’d be surprised how easy it is to wet sand plastic back to a shinier, more uniform appearance.

When wet sanding plastic, use irregular motions to avoid deep scratches. You can use a circular motion similar to that used with dry sanding. Just be sure not to repeat the same path, as you could end up shaping a valley in the plastic with your motions.

If you’re wet sanding a broad, flat section of plastic, you might find it helpful to use a foam block. You can also wet sand plastic with toothpaste, baking soda, or vinegar. Just be sure to wear gloves and prepare your work area accordingly. If you are applying paint to your plastic surface, you can also wet sand the primer before any base coat goes down. For more on how to wet sand primer, check out the automotive section below.

Drywall Wet Sanding

If you’re not confident in how to wet sand drywall, you’re not alone. There are many techniques you can use with wet sanding drywall, but the basic process allows you to smooth out drywall without creating clouds of harmful, super-fine dust. It may take longer to wet sand drywall than dry sand it, but the health benefits definitely outweigh time constraints.

The first step in learning how to wet sand drywall begins with understanding that less is more. While some applications of wet sanding may require dowsing your project in lubricant, drywall does not fall into this category. Instead, you’ll want to control how much water you’re using to avoid damaging the drywall with valleys, craters, and melted spots.

Before you look up “how to wet sand drywall,” know that this process is often referred to as “joint smudging” as well. Technically, you’re not so much sanding as smoothing out any drywall compound that’s sticking up. Most often, this is done with a thick, stiff sponge that’s two-sided. One side retains medium-grit sandpaper, while the other is much finer.

The basic process of wet sanding drywall begins with dampening the sponge and knocking down the high spots of drywall compound using the medium-grit side. You’ll want to use circular strokes and wash your sponge out when it becomes dirty. One or two passes should be enough, as more can potentially soak the surrounding drywall and create more problems. You can then use the fine side of the sponge to wipe away drips and ensure a smooth finish.

Wet Sanding a Car

If you’ve wanted to learn how to wet sand a car, clear coat, headlights, or paint, the automotive industry is the place to be. Body shops will often perform these repairs and may even teach you how to wet sand clear coat and buff out the paint afterward.

Knowing how to wet sand headlights can help you understand the basic process of how to wet sand paint as well. Headlights are often plastic or glass and can have a buildup of residue from being on the road. Polishing these headlights simply takes a bit of wet sanding to remove the film, and polishing to up the shine.

It’s common to use 1500- and 2000-grit sandpaper when wet sanding both headlights and automotive paint. In some cases, you may need to break out the 1000-grit sandpaper for headlights, but this is often not the case with paint. Scratches deeper than what 1500-grit sandpaper can pull out simply require repainting.

You’ll use a similar process with automotive surfaces as you would with plastic when wet sanding. Small circles with a light touch work best for paint, while headlights may require more attention in certain spots than others, depending on the contours of the headlight itself. As you gain more experience in how to wet sand headlights, you’ll have the foundational skills required for wet sanding paint and clear coat.

If you know how to wet sand paint, you understand how to wet sand primer. At the same time, it’s critical to understand that wet sanding will remove paint. Specifically, it will remove the clear coat and paint down to the primer and past if you’re aggressive enough. That’s why it’s often best to practice wet sanding paint of various thicknesses to gain experience. You can also use a paint meter gauge to measure the paint thickness on a vehicle. Be aware, however, that the thickness reported by a paint meter includes the entire coating, from the primer and paint to the clear coat.

Wet sanding is often used between automotive paint and finish layers. To achieve a smooth, flawless appearance, the primer must be wet-sanded to near perfection. That means looking down the door panel, hood, or trunk lid and not seeing a single hill or valley. However, latex paint primers don’t require sanding. While the base coat doesn’t get wet sanded, body shops often wet sand a clear coat to achieve that new-car finish you’re used to seeing. There’s a lot more to knowing how to wet sand a car than first meets the eye.

Wet Sanding a Boat

If you’re not sure how to wet sand a boat, don’t stress. Even if you’ve had some experience with wet sanding a car, tackling a boat can be a whole other animal. The difference lies in working with a gelcoat instead of paint, which can often be wet sanded in fewer steps than automotive paint. Like automotive paint, however, you don’t want to strip the gelcoat away.

The goal of learning how to wet sand a boat is to remove the dead gelcoat and reveal the fresh coat underneath. This requires wiping off any oxidation first by hand. There are many products you can use to accomplish this task before you start wet sanding.

In contrast to automotive wet sanding, wet sanding a boat requires you to begin with finer-grit sandpaper and only revert to a coarser grit if necessary. Keeping the hull wet can be difficult and messy in learning how to wet sand a boat, but it’s rewarding when you see the results of your work.

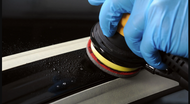

It’s common to use a dual-action (DA) sander when wet sanding a boat. You can use an electric DA sander if you want, but air sanders often work best in wet situations. Of course, you’ll need an air source and an air attachment hose in addition to the air-specific DA sander.

As you buff the gelcoat, you’ll want to work in a perpendicular pattern similar to what we spoke of with plastic wet sanding. Move side to side down a two-foot by two-foot section of the hull, and then work up and down. This motion will help you achieve a uniform finish. For smaller details near the edges of the boat, you’ll need to use hand sanding techniques and an interface pad. Then, it’s a simple question of buffing the gelcoat back to its shiny state.

Wood Wet sanding

Figuring out how to wet sand wood may seem counterintuitive. After all, wood and water don’t often seem to mix with any positive results. So, how and why should you wet sand wood?

The truth of the matter is that you typically won’t wet sand bare wood. Instead, you’ll probably hear the term “rubbing out” in place of wet sanding to describe a process of removing fine dust particles without disturbing the grain of the wood. This process requires a measured approach, as you don’t want to soak the wood with water. That’s why woodworkers often use spray bottles to keep their sandpaper wet.

The most important step in wet sanding wood is to allow it to dry between processes. This gives the pores of the wood time to dry so that you don’t have any issues down the road. Pores that aren’t completely dry can leak water, which will dilute any stains or finishes you use thereafter. If you do end up finishing your wood project by waxing it, the water can repel the wax finish and leave the surface untreated as well. It pays to know how to wet sand wood.

Metal Wet Sanding

Wet sanding metal takes a little bit of degreaser, some wet sandpaper, elbow grease, and time. You can also use WD-40 to polish metal, as we mentioned previously.

Begin by wiping your metal surface with a degreaser and wiping it clean. Use an orbital sander with low-grit sandpaper or sand by hand, being careful to incorporate a fair amount of water as you do so. When you feel the surface is sufficiently sanded, wipe it clean and degrease it once more. You’ll repeat these steps, increasing your sandpaper grit with each step until you reach your desired finish. Note that it’s important to keep your surface wet. You should also degrease the metal one final time before it’s ready for the next step, whether that’s painting, anodizing, etc.

Polyurethane Wet Sanding

The trick to knowing how to wet sand polyurethane to achieve superior results relies on allowing the polyurethane itself to cure completely. If you’re dry sanding this material, you only have to wait about 24-48 hours. For pieces to cure completely, however, could take about a week or more depending on the conditions and what type of polyurethane you used. Water-based polyurethanes take about two weeks to cure fully, while darker oil-based polyurethanes can take up to a month.

When your polyurethane piece has sufficiently cured, you’ll use a similar approach to all the processes we’ve described above. Work from a harsher grit down to a finer one, ensuring you keep the piece well-lubricated the entire time. Larger pieces can require a power sander for efficiency, but it’s often best to sand by hand with smaller pieces. Power sanders tend to create hot spots directly beneath the head of the sander, which can damage small pieces that can’t disperse the heat fast enough.

FAQs

Is there wet sanding-specific sandpaper for wet sanding?

Yes, there is wet sanding-specific sandpaper. If you’re looking for sandpaper you can wet sand with, ensure that it’s specific for this use. Using dry sandpaper for wet sanding purposes can cause several issues, including damage to the surface you’re sanding.

Why should I use a backing pad with wet sandpaper?

You should use a backing pad with wet sandpaper based on the purpose of wet sanding. Where dry sanding removes a lot of material and roughs in the final shape, wet sanding polishes that shape with minor changes. Small inconsistencies with the wet sandpaper can result in less-than-desirable results.

Is it better to wet sand by hand or with a power tool?

By far, most experts will recommend wet sanding by hand versus a power tool. Again, this goes back to using the right tool for the job based on where you are in the process. Power tools can remove a lot of material quickly. However, wet sanding with your hands can help you refine small edges, details, and other components that require a careful touch. It’s also easier to feel discrepancies in the surface with your hand than a power tool, at least in most case

Can you wet sand the orange peel out of car paint?

Yes, it is possible to wet sand the orange peel look out of car paint. Automotive paint looks like orange peel because there are many high spots in the paint as a result of the painting process. Wet sanding can knock those high spots down for a more uniform result that shines.

Final Thoughts on Wet Sanding

Wet sanding various materials can help you bring projects and possessions to a higher standard. No matter if you’re working with plastic, metal, automotive finishes, or polyurethane, wet sanding can go a long way in achieving that silky smooth finish associated with professional-grade products.

We offer several wet sanding products you can use, from wet/dry sandpaper to sanding discs and more. These quality products can help you go that extra mile without going over budget. Check out our line of wet sanding sandpaper products made for getting the job done right. What materials will you wet sand next?