Sanding the Curves

Posted by The Team at 2Sand on 05 23 2023

2 Inch Disc and Mandrel Set

In most cases sanding is done on mostly flat surfaces, but some sanding jobs just need to follow the curves. Sanding down a small outboard propeller for repainting is a perfect example. Not only are all the surfaces compound curves, there is very little space to work. So, this job is going to require unusually flexible sanding supplies.

A 2 inch Mandrel was chosen as the starting point to best fit in the tight areas where the blades meet the hub. The 2” Bowl Sanding Disc and Mandrel Set, (WR2Kit4Grit) is the place to start, providing the mandrel and an assortment of discs from 60-220 grit. The mandrel pad is flexible enough for most curved parts, but this particular job needed more, so a 2” Very Soft Grey Interface Pad 3/4” Thick (IP-VS-2) was added to the mandrel. Turning in an electric drill or air-powered die grinder, this combination allows the sanding disc to conform to complex surfaces, applying more uniform pressure on both the concave and convex surfaces of the blades. It makes quick work of removing old paint and corrosion from the prop blades.

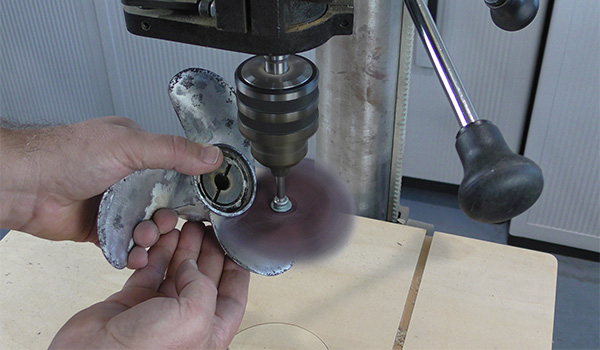

As flexible as this set up is, the joints between the blades and the hub were not reached quite as well as needed, so these were finished at the drill press using the shop-built mop sander we just showed you how to build in the March 14th edition of the 2Sand Blog. Any minor touch ups were completed using some of the different grits available with the 4 Sided Sanding Sponges or the Sanding Detailer Stick Finishing Kit.

Some sanding supplies like sanding sheets and sanding discs are kept in stock for general use on most projects. But every so often a job comes along needing something a little more specialized. When this happens, you can find what you need at 2Sand.com, get it delivered fast, and at a fair price.